Laser Cutting

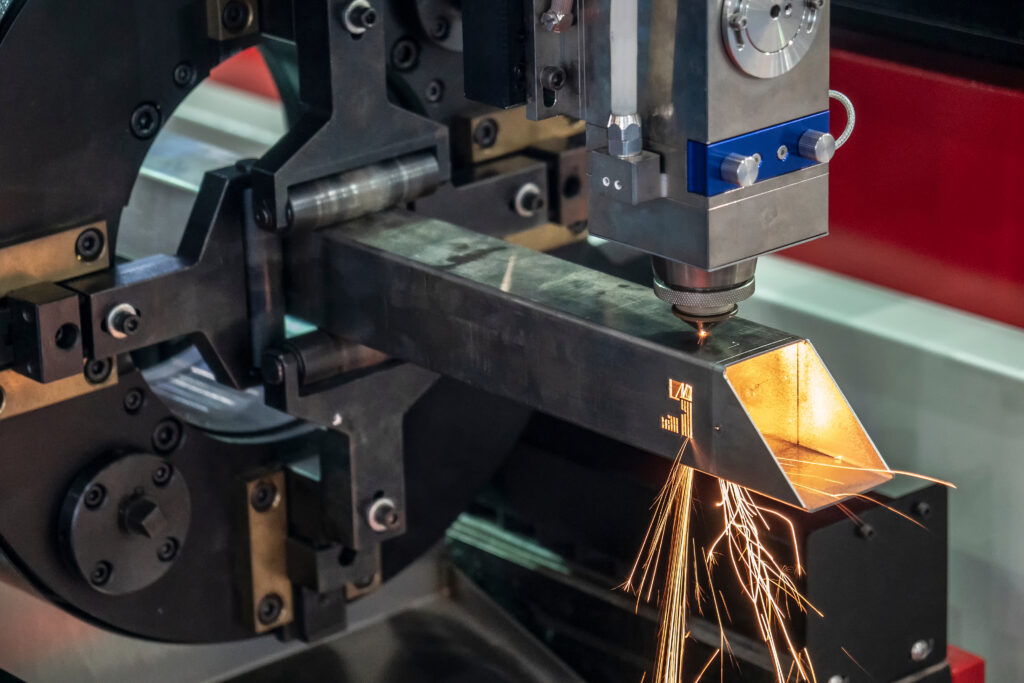

At EMS Group, we specialize in offering innovative and efficient laser cutting solutions, focusing on sheet metal and tube cutting services. Thanks to our advanced technology and an ongoing commitment to quality, we are able to provide exceptional results that meet our customers’ highest expectations.

Laser Sheet Metal Cutting

2D fiber laser cutting is the ideal choice for those looking for high-precision cuts. This method minimizes or eliminates the need for additional processing after cutting, allowing immediate use of the resulting parts. The efficiency of our laser cutting is enhanced by its outstanding speed, which translates into a noticeable reduction in costs and time compared to traditional methods.

Benefits of Laser Sheet Metal Cutting

- High Precision: We guarantee cuts with minimum tolerances, ensuring that each part meets the required specifications.

- Reduced Costs and Time: Cutting speed improves production efficiency, resulting in decreased operating costs.

- Flexibility in Materials: We work with a wide variety of materials, including carbon steel, stainless steel, aluminum, copper and brass, adapting to the specific needs of each client.

In addition, our 3D laser technology with 5-axis rotary head allows us to take cutting to a higher level, while maintaining the ability to work on any molded sheet. This provides an ideal option for complex designs and custom parts that meet your requirements.

Laser Tube Cutting

Tube laser cutting at EMS Group is an advanced manufacturing technology that employs high-precision lasers to cut metal tubes and profiles cleanly, efficiently, and accurately. This method allows us to shape a wide variety of geometries and sizes, ensuring a superior finish on each component.

Benefits of Laser Tube Cutting

- Precise and Clean Cutting: Our technology ensures accurate cuts in tubes and profiles, including UPN, IPE, L, and plates, resulting in clean, well-kept edged parts that require little to no additional processing.

- Complex Geometry Capability: We can work with a variety of profiles and configurations, adapting to the most demanding specifications of our customers.

- Material Versatility: We are capable of cutting pipes of various materials, such as carbon steel, stainless steel, copper and brass, providing solutions adapted to multiple industrial applications.

The fast cutting speed of our laser equipment also favors the improvement in production times, allowing us to meet tight deadlines and optimize costs in each project.

At EMS Group, we understand that quality is critical at every stage of the production process. Our team of experts is dedicated to ensuring that our laser cutting services are performed with the utmost precision and attention to detail. We use state-of-the-art machinery to ensure that every project, large or small, meets the highest industry standards.

What are the advantages of ordering laser-cut parts from EMS Group?

- Expand your production capacity.

- Consult with EMS Group engineers about your laser cutting project to find efficient and economical solutions.

- EMS Group takes care of the entire process, from quotation to delivery, including quality control.

- A single point of contact makes project management easier, allowing you to focus on tasks that add more value.

Material Selection

Laser Sheet Metal

- Carbon steel: up to 25 mm

- Aluminium: Up to 12 mm

- Stainless steel : Up to 25 mm

- Other materials and alloys : Consult

In addition, we work with galvanized materials, brass, copper, and more. Trust us for flawless laser cutting results, tailored to your specific needs. The excellence in precision and versatility of our services makes us the ideal choice for the manufacture of high-quality metal parts.

Laser Tube

As with laser sheet metal in tube laser you can cut all kinds of metals (carbon steel, stainless steel, aluminum, titanium,…. ). The choice of CO2 cutting or fiber cutting will depend on whether these are reflective such as copper, brass and aluminum.

We can cut tubes and profiles, offering a comprehensive service covering diameters from ø12 mm to ø700 mm. We can also use angle profiles, UPN, IPE…. In reference to the thicknesses that we can cut with laser tube we recommend you contact us.

Delivery time

The average delivery time is 7 days.

Precision

In our commitment to excellence in laser cutting, we provide our customers with the choice between CO2 or fiber laser cutting, adapting to their specific needs. We stand out for the use of nitrogen cutting, guaranteeing clean and precise cuts without calamine on the edges. Our laser cutting technology offers extraordinary precision, reaching up to 0.2 mm. Whether you’re looking for the versatility of CO2 or the speed and efficiency of fiber, trust us to exceed your expectations with flawless, highest-quality laser cutting results.

Quality Control

Our quality control department performs robust quality control. EMS Group is ISO 9001 certified.

Frequently Asked Questions About Laser Cutting Services

What is laser cutting?

Laser cutting is a manufacturing process that uses a highly concentrated laser beam to cut or engrave materials. This technique is widely used in various industries due to its accuracy, versatility, and efficiency.

What is fiber laser cutting?

Fiber laser cutting is a type of laser cutting that uses a high-power laser beam focused through a fiber optic cable. The fiber optic cable is made up of flexible glass fibers that guide the laser beam to the cutting head. Allowing the laser beam to be focused on very small points to obtain high precision in cutting.

What is CO2 laser cutting?

A CO2 laser is a laser that typically uses a mixture of gases to produce a high-powered laser beam to cut, engrave, and mark materials such as metal, plastic, and wood.

CO2 laser machines can use both oxygen and nitrogen. Thicker materials are usually cut using oxygen. The disadvantage of cutting with oxygen is that a layer of oxide (calamine) forms on the cutting surface and more spatter occurs. This layer can come off, which is not desirable if the parts are not subsequently treated (shot blasting). In the case of nitrogen, a clean cutting surface is created without rust film.

Can you provide me with material certificates?

Yes we can! If you need a material certificate, please indicate it in your practice.

Do you offer manufacturing consulting?

Yes, our customers can count on the professional guidance of our manufacturing engineers, who have extensive experience to help them identify the most suitable and economical option to produce their parts.

If you are looking for high-precision sheet metal or tube laser cutting services for your projects, do not hesitate to contact us. We are here to offer you customized solutions that are tailored to your specific needs. Request more information or a quote and find out how we can help you.

At EMS Group, quality and efficiency are our priority!